& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Artificial intelligence (AI) in manufacturing applies the power of machine learning and neural networks to produce decision-making insights based on system-wide data collection. This can enhance productivity, efficiency, and accuracy across all manufacturing processes. AI for manufacturing can exist in software that optimizes design for manufacturing, in robotics systems that maximize productivity and efficiency, in Industrial Internet of Things (IIoT) devices that collect data streams from sensors, and within cloud computing that networks a connected smart factory into a unified system.

AI first impacted the industrial sector in the 1970s, with the advent of early computer-assisted design (CAD) software and computer numerical control (CNC) machines. By the late 1980s, simple AI within robotics systems helped boost manufacturing productivity and efficiency by automating repetitive tasks. After some stagnancy in the 1990s, AI for manufacturing exploded in the 2000s with machine learning that could analyze large datasets to inform certain decisions and optimize certain processes.

Ever since then, AI and machine learning’s abilities have expanded and transformed traditional manufacturing. For example, it elevates quality control by accurately detecting manufacturing defects and can promote sustainability by finding efficiencies in energy use, material use, and preventing rework. AI’s data-driven predictive maintenance avoids downtime by scheduling repairs before failures occur. AI and robotics can automate production lines and augment the human workforce by providing actionable insights and better safety conditions. AI can streamline supply chains by forecasting demand and optimizing the logistics of transportation and inventory.

The latest generative AI also benefits manufacturing by automating scheduling and resource allocation. At the product design stage, the old way involved engineers designing something, then someone else figuring out how to manufacture it. But now, the software can determine manufacturability simultaneously as the designers and engineers develop the product using highly connected data, simulation, and AI-augmented design capabilities driven by integrated CAD/CAM/CAE AI manufacturing software like Autodesk Fusion.

Machine learning, an algorithmic subset of AI, makes it possible for systems to automatically improve from experience. It thrives off of data, and its utility grows by analyzing the constant data streams collected from Industrial Internet of Things (IIoT) sensors such as lidar, radar, ultrasound, force sensors, computer vision, and others. Among its many advantages, machine learning enables predictive maintenance, which is the ability for AI systems to monitor equipment’s condition, predict when a machine will need maintenance, and schedule that maintenance for a convenient time, avoiding costly downtime.

Off the assembly line, machine learning also confers other benefits like the ability to improve quality assurance by inspecting products for defects better than humans can. And machine learning can analyze centralized data from digital factories to streamline supply chains by optimizing logistics routes and warehouse space, managing inventory with computer vision, and more.

While assembly-line robotics and automation have existed for many years without AI, robotics and automation in Industry 4.0 are powered with AI and have greater sensing, communicative, and decision-making abilities. They also have greater mobility and configurability and gather an enormous amount of cloud-connected data to contribute to a smart factory. The growing phenomenon of cobots (collaborative robots) are better equipped with sensors and AI to safely interact directly with people, doing tasks like gathering and distributing materials throughout a facility.

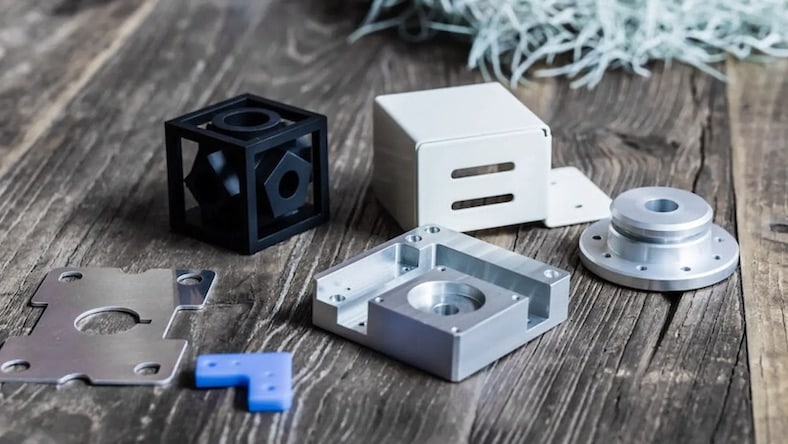

AI affects the pre-production stages of manufacturing through generative design using software like Autodesk Fusion. Generative design does not always use AI, but very often it utilizes machine learning to rapidly cycle through many thousands of design options that meet the designer’s constraints, coming up with iterations that a human likely never would. Generative design can solve for the size and strength requirements of a design, while also often lowering the weight, material use, and cost. In addition, the computer-aided manufacturing (CAM) abilities of AI manufacturing software like Fusion can find the most efficient methods for producing generative- and human-designed parts, making mass customization via 3D printing and CNC machines easier.

The combination of AI and manufacturing plays a key role in the realization of Industry 4.0 in a digital factory, where a digital twin of a physical facility incorporates data tracking everything from the smart machines and robotics on the factory floor to energy use and workforce behavior. To consolidate the competitive advantages of the transformation to a digital factory, existing employees may need significant reskilling and upskilling to adapt to working in an AI-infused smart factory.

Part of reskilling can be getting used to replacing paper with digital files and replacing spreadsheets with automation. More significant reskilling to adapt to smart machines and systems can be done gradually and with digital tools like simulation software and extended reality (XR) headsets so that workers can learn without necessarily disrupting production. Embracing apprenticeship and cross-generational mentorship, where older employees help the younger with legacy systems, while younger workers assist the older with high-tech skills, can also aid in the transition.

As AI enables more automation, workers should learn hard skills like fluency with data-driven, AI manufacturing software tools for analytics and planning. However, human-centric soft skills like collaborative problem-solving, critical thinking, creativity, and emotional intelligence are also becoming more important.

The data processing and automation powers of AI for manufacturing result in a host of benefits, from safer working conditions to resource efficiency and reduced costs.

AI in manufacturing can analyze product images and data to detect defects more accurately, leading to quality control cost savings from reduced scrap, rework, and returns. AI can also optimize production processes, scheduling, and resource allocation for further cost savings.

Use of AI in manufacturing offers predictive maintenance—the ability to pinpoint potential machine failures in advance by analyzing historical data and real-time sensor info. This prevents downtime from unexpected breakdowns and instead allows maintenance to be scheduled during planned downtime.

AI-powered data analysis scans market trends, sales records, and other factors like seasons and holidays to forecast future demand. This lets manufacturers optimize inventory levels, production planning, and resource allocation accordingly.

With its ability to calculate the most efficient production processes, like cutting patterns, or scheduling materials to be used before they degrade, AI in manufacturing can make the most efficient use of raw materials.

Just as AI can predict equipment failure before it happens, AI safety monitoring equipped with computer vision and data analysis can predict and alert manufacturers to potential hazards, preventing accidents by analyzing worker behavior and environmental and equipment conditions.

Logistics and supply-chain data feed AI systems, which can predict and optimize the best transportation routes for on-time delivery, reduce lead times, and provide transparency across manufacturing supply chains.

Optimize part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection molding, and more.

Get Inventor + AutoCAD + Autodesk Fusion + more—Professional-grade tools for product development and manufacturing planning.

Powerful product design and engineering tools for 3D mechanical design, simulation, visualization, and documentation.

VISICONSULT

As part of VisiConsult’s digital transformation, the leading manufacturer of industrial X-ray equipment is developing an AI platform that automates image evaluation and inspects parts even more reliably than conventional film-based image processing.

TOYOTA

Find out how Toyota is experimenting with AI-based tools such as generative design to create car seat frames that meet all the requirements for safety, comfort, and performance while reducing the material used and the space required in the cabin.

Image courtesy of Toyota

MISUMI

This Japanese made-to-order manufacturing equipment parts company with a gargantuan 80-sextillion product catalog uses AI to generate cost and lead time estimates for custom parts and to speed up the procurement process.

Image courtesy of MISUMI

The head of Autodesk Research explains how generative AI and generative design are making product development faster while also resulting in better-engineered products. For example, the Mercedes Formula One team made a better rear suspension part while shortening the manufacturing process from six weeks to 48 hours.

Find out how Autodesk AI can automate, analyze, and augment manufacturing workflows, reducing time spent on tedious work by, for example, automating the documentation for 2D design drawings, automating repetitive CAM toolpaths, automated modeling abilities, and more.

The machine learning properties of generative design contribute to AI manufacturing by producing cost-effective parts that can retain strength properties while reducing the materials needed.

The experimental Bernini AI model generates multiple variants of functional 3D shapes from inputs of text, 2D images, voxels, and point clouds. With additional training on large, high-quality datasets, Bernini will become more useful for industries like manufacturing and engineering.

Watch an intro to the Digital Material Engineer from Autodesk Research and Ansys. The tool takes plain-language text from designers to automate the tedious parsing of relevant information from a database of over 4,000 materials. Data visualization shows qualifying materials and their impacts on cost, manufacturability, environmental impact, and more.

There’s much more to AI for manufacturing than just ChatGPT. However, implementing AI into manufacturing workflows in an impactful way is a major challenge. Autodesk supports manufacturers integrating powerful AI into their workflows with APIs for manufacturing software, including Fusion, Inventor, and AutoCAD.

AI is used in manufacturing in many capacities that can increase efficiency while decreasing costs. Some of the top use cases for AI in manufacturing include predictive maintenance, predicting product demand, product development, supply chain and warehouse management, assembly line and performance optimization, cobots, and connected factories that streamline the automation of assembly lines, order management, and clerical tasks.

Gathering data from McKinsey, IBM, Forbes, and Sortlist, Exploding Topics reported that that 35% of the 333.3 million companies worldwide used AI in their business as of March 2024, and that more than 50% of all companies plan to incorporate AI in 2024.

The AI market in manufacturing was reportedly $3.2 billion in 2023, and is predicted to hit $20.8 billion by 2028, according to a recent report from MarketsandMarkets. Another recent survey from Augury showed that 63% of manufacturers planned to boost spending on AI in 2023.

When it comes to the adoption of generative AI specifically, manufacturing is one of the most primed industries. According to the Dresner Advisory Services 2024 Edition Generative AI Report, about 85% of manufacturing firms are either excited or cautiously optimistic about adopting generative AI.

Generative AI can be used in many ways for manufacturing. For example, generative scheduling can automate production planning and resource allocation, arriving at the maximally efficient solutions in a fraction of the previous time required. Generative AI models trained on internal company data can also be a source of quick troubleshooting support to workers, which can increase job satisfaction and productivity.

Generative design within software like Autodesk Fusion often uses AI and machine learning but is different from generative AI, in that it focuses on creating physical designs and prototypes.

The challenges of AI in manufacturing relate largely to implementation, human resources, and data. Implementing AI into manufacturing operations takes significant planning and investment to customize AI systems and align them with a firm’s needs. The new knowledge and skills needed to work with AI systems also may require new hires, outsourcing, or upskilling and training the existing workforce.

Data quality and security are also paramount. AI and machine learning thrive on quality data, so organizations need to set up for collecting the right data and make sure the data is accurate and secure to protect from cyber threats.